♦ IS YOUR POOL SAFE ? ♦

Lightning strikes over swimming pools are more common than you might think.

To achieve peace of mind proper bonding is required.

Bonding Analysis

For those who know Statewide Homes, know that we’re huge advocates of public safety. Being cognizant of hazards throughout the property is an integral part of the daily job as inspectors and consultants.

It is our opinion that Swimming pool safety is one of the most important areas of the property and the pool electrical system NO EXCEPTION.

Bonding of the swimming pool is one of the most difficult concepts of swimming pool safety to understand for many electricians, pool builders and Realtors. You might be wondering how come I lumped Realtors in this group. Well, I included realtors in this group of individuals because in many cases they are on the front lines of this specific issue having being on the selling end or buying end of transactions where these issues are usually discovered during the home inspection.

It also my own personal opinion that many of the real estate agents do not grasp this concept or importance of Bonding and as a result, can unknowingly place their clients in direct harms way and in some cases just to move a deal forward. As a home buyer, however, it is my suggestion that the buyer let a pool builder and expert inspect the pool and guide the buyer in their decision-making process.

How Old is the Pool bonding Requirement code?

Swimming pool bonding appears to have been established for quite some time now. My 1968 copy of the NEC book appears to mention the need for a #8 AWG bonding conductor for the first time.

680-7. Grounding

– (a) All metallic conduit, piping systems, pool reinforcing steel, light fixtures, and the like, shall be bonded together and grounded to a common ground. The metal parts of ladders, diving boards, and their support, shall be grounded.

– (b) No pool equipment shall be grounded to an external grounding electrode that is not common to the pool ground (deck box or transformer enclosure).

– (c) An unbroken No. 14 AWG, or larger, insulated copper wire shall be provided for a grounding conductor from the deck box to the distribution panel ground.

– (d) Metallic raceways shall not be depended upon for grounding. Where exposed to pool water and in other corrosive areas such as in pump houses or adjacent to water treating and other equipment, the grounding of the non-current carrying parts shall be by means of an insulated copper conductor sized in accordance with Section 250-95.

GRANDFATHERED?

I hear this term “grandfathered” often during my inspections. The simple definition of Grandfathered is that a component or system was installed or constructed prior to the most current code cycle. There are still questions as to whether the issues present can be accepted simply because they may have been present long before a building code was ever established.

What I do hear often is…”it’s been like that for over 50 years and nobody has been killed yet.” Hearing this makes me cringe every time because somehow the realtors or sellers use this to make a point that because nobody has died or have been injured to date, (that they know of) somehow this makes the situation safer? Okay…so with that philosophy why bother installing GFCI receptacles close to water? Or why bother installing safety glass in areas close to water, or what about fire-stopping? While were at it, why did they even bother updating the codes to necessitate fire sprinklers? I mean really…those code people are so ridiculous, right?

Codes change because people are injured or worse, die. Building codes also change for protection of people and property. As a matter of fact, those code people are brilliant, and are forward thinkers.

As inspectors and contractors we understand that issues do not have to be brought to a newer standard. When we make mention of missing components or systems it’s always out of prudence and protection of the buyer and their family.

HERES WHAT THE CODE SAYS ABOUT EXISTING STRUCTURES

R102.7 Existing structures.The legal occupancy of any structure existing on the date of adoption of this code shall be permitted to continue without change, except as is specifically covered in this code, the international Property Maintenance Code, the international Fire code, or as is deemed necessary by the building official for the general safety and welfare of the occupants and the public.

Buildings that exist legally at the time the code is adopted are allowed to have their existing use and occupancy continued if the use or occupancy of the structure was also legally in existence. This means that as long as a structure or building remains in a safe and sanitary condition it need not be upgraded to meet the more current standards. However, any new construction, addition or remodeling will require such work to conform to the requirements of the new code. A change of occupancy of the building also will force the building to conform to the new standards. The existence of a building prior to the adoption of a new edition of the code does not grant it the status of a legal existence. A building is thought of as being grandfathered. under prior rules and not needing to be brought up to current requirements when there are records to show that it was constructed to meet the regulations of the jurisdiction in force at the time it was built. The most common way to demonstrate legal compliance with the construction codes of a community is through the public records. Copies of past building permits can be researched at the jurisdictional archives. Upon discovery that a building does not have a legal existence, corrective actions will be needed in order to bring the structure into compliance with the regulations of the jurisdiction at the time the building was built.

BEFORE WE START

Even before we get into the bonding discussion, it’s important to understand the difference between grounded and bonding as explained by the NEC;

GROUNDED

The connection of metal parts to earth for the purpose of directing lightning and other high voltage surges into the ground.

BONDING as defined by Mike Holt (electrical expert);

The permanent joining of metallic parts to form an electrically conductive path that ensures electrical continuity, and the capacity to conduct safely and fault current that is likely to be imposed. Bonding is intended to create a low impedance path for the purpose of removing dangerous touch voltage from metal parts from a ground fault by quickly opening the overcurrent protection device (breaker). BONDING IS NOT GROUNDING.

Putting it together

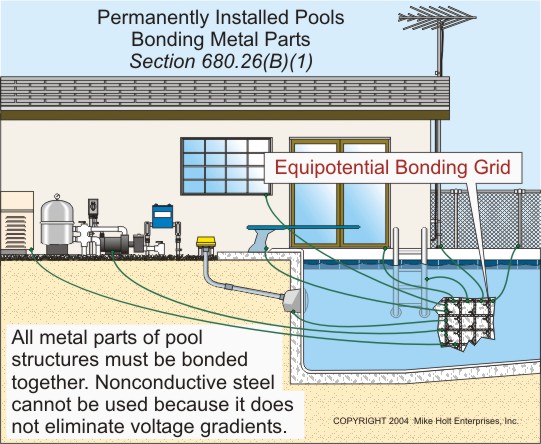

In accordance with the NEC section 680.26 (a); The Equipotential bonding required by this section shall be installed to reduce voltage gradients in the pool area. Bonding as just described differs from the primary function of bonding as many electricians are already familiar with as describe in article 250 of the NEC, which states the function of bonding is to provide a low impedance path for ground fault current.

In order to create an environment which is safe electrically around a swimming pool requires a bonding system as in accordance with NEC 680.26, with its primary function being, establishing a grid to equalize the voltage potential in the area of the swimming pool. Even while swimming or relaxing on the pools deck surface (which are conductive parameter surfaces) they are subject to voltage difference in voltage which may be present within a pool area. Components (and water) are bonded together with a solid #8AWG copper conductor with connections / methods listed in (250.8(a)). Equipotnetial bonding is not required, however, to extend to any service panel, service equipment or Grounding electrode like a GROUND ROD.

Equipotential Bonding Requirements

Bonding requirements are an important and unique protective method employed to increase the safety of the users of bodies of water such as pools, spas, and hot tubs. Bonding connects the conductive elements of the pool structure, nearby metallic objects, and electrical equipment enclosures together. Bonding is required to eliminate voltage gradients (rises in voltage potential) in the pool area. When metallic parts are bonded together, they effectively eliminate differences of voltage potential that may exist between the individual conductive parts and thus reduce the shock hazard. If these metallic conductive parts are not bonded together, this leaves these conductive parts having the potential of being at different voltage potentials. In a case like this, the human body can serve as a “conductor” between two conductive parts at different voltage potentials if contact is made with these conductive parts. If a conductive path is provided between two conductive parts at different voltage potentials, this current is going to naturally equal itself out between these conductive parts. An electrical shock occurs when the human body is used as the “conductor” between these conductive parts. If these conductive parts are mechanically, electrically, and intentionally bonded (married) together, there is typically no shock hazard present as these conductive parts are always at the same voltage potential.

This bonding is referred to as equipotential bonding [NEC 680.26(A) and (B)]. Once called the “common” bonding grid, it was changed to “equipotential” bonding during the 2005 NEC to help clarify and describe the function and purpose of this section.

Now is a good time to explore the different purposes served by bonding and grounding and to develop a clear understanding of the two terms. Bonding is used to equalize voltage potential differences to reduce shock hazards between different parts of the pool by connecting potentially conductive parts together. Grounding involves providing a low-impedance, ground-fault return path from the equipment required to be grounded back to the source of the electrical system, typically through the equipment grounding conductor routed with the branch-circuit conductors. This path facilitates the operation of the fuse or circuit breaker to allow it to remove the faulted condition. In short, bonding means “connected together,” while grounding means “connected to earth.” Grounding and bonding together provide the safety from shock hazards that is so important, particularly in an aquatic environment such as a swimming pool.

Since several types of electrical equipment commonly used with swimming pools, hot tubs or spas that are bonded together must also be grounded, an interconnection between the grounded (neutral) conductor and bonding grid exists. This interconnection, usually at the electrical service equipment, is often remote and is not intended to play a part in equipotential bonding (see figure 1).

Figure 1. Bonding and grounding of pool associated components and equipment

Swimming pools, spas, and hot tubs present special shock hazards to people.

The water is mixed with chemicals, which often INCREASE CONDUCTIVITY.

People are in direct contact with the water and encounter grounded objects such as metal ladders.

Electrical equipment is used to circulate and heat the water and for other related functions such as illumination.

The Code requirements, if carefully followed, will reduce the electric shock hazards to an acceptable level. One of these measures is the bonding together of conductive portions of the pool and metal parts of electrical equipment associated with the pool. The goal is to provide a means of equalizing the voltage potential of all equipment and parts. If done properly, there will be no current flow between these parts that would be harmful to personnel. The required bonding is accomplished by connecting all the parts together by an adequately sized and properly connected series of copper bonding conductor(s) or other recognized bonding methods.

The Code describes the basic bonding requirements and provides a list of items required to be bonded together. These bonding requirements can be found at NEC 680.26(B).

Included are the following metal parts that must be bonded together:

-

All metal parts of the pool structure, including the reinforcing metal of the pool shell, coping stones and deck. The usual steel tie wires are considered suitable for bonding the reinforcing steel together, and welding, brazing or special clamping is not required. These tie wires must be made tight. Reinforcing steel effectively insulated by an encapsulating, nonconductive compound at the time of manufacture is not required to be bonded. If this is the case, the Code requires provisions to be made for an alternate means to eliminate voltage gradients. This alternate means will be discussed later in this article.

-

All metal forming shells of wet-niche luminaires and mounting brackets of no-niche luminaires. Listed low-voltage lighting systems with nonmetallic forming shells are not required to be bonded. Check the manufacturer’s instructions for installation details to ensure compliance with listing requirements.

-

All metal fittings within or attached to the pool structure. Isolated parts that are not over 100 mm (4 in.) in any dimension and do not penetrate the pool structure more than 25 mm (1 in.) such as a metal rope hook or loop are exempted from the bonding requirement.

-

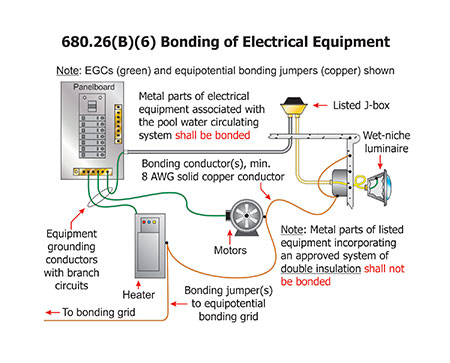

Metal parts of electric equipment associated with the pool water circulating system, including pump motors and metal parts of equipment associated with pool covers, including electric motors. It should be noted that metal parts of listed equipment incorporating an approved system of double insulation, such as a double-insulated pool pump motor, are prohibited from being bonded to the equipotential bonding grid.

-

Metal-sheathed cables and raceways, metal piping, and all fixed metal parts that are within 1.5 m (5 ft) horizontally of the inside walls of the pool, and within 3.0 m (12 ft) above the maximum water level of the pool, or any observation stands, towers or platforms, or from any diving structures, that are not separated from the pool by a permanent barrier.

-

The pool water itself must also be bonded. An intentional bond of a minimum conductive surface area of 5800 mm2 (9 in.2) is required to be in direct contact with the pool water. This bonding can be accomplished with any of the conductive parts that are required to be bonded as described above. This could include such things as a metal pool ladder or railing where at least 9 square inches of the ladder is in contact with the water. A metal forming shell of a wet-niche luminaire can also satisfy this bonding requirement [see NEC26(C) and photo 1].

-

For pool water heaters rated at more than 50 amperes and having specific instructions regarding bonding and grounding: only those parts designated to be bonded are required to be bonded; and only those parts designated to be grounded are required to be grounded. As stated previously, accessible metal parts of listed equipment incorporating an approved system of double insulation and providing a means for grounding internal non-accessible, non−current-carrying metal parts are not permitted to be bonded by direct connection to the bonding grid. The equipment grounding conductor run with the supply branch circuit conductors to the motor is the permitted means used to ground the internal non-accessible metal parts of these double-insulated motors.

-

Where a double-insulated water pump is installed, a bonding connection to the equipotential bonding grid is not permitted. However, the Code does require the installation of an 8 AWG solid copper bonding conductor that is of sufficient length to make a bonding connection to a future replacement motor. This requirement is in the event that the replacement motor is not a double-insulated type motor. The bonding conductor is to be extended from the equipotential bonding grid to an accessible location near the motor. Where there is no connection between the bonding grid and the equipment grounding conductor for the premises, this bonding conductor is required to be connected to the equipment-grounding conductor of the pump motor circuit. This connection could be made at the motor termination compartment or in a suitable junction box or other enclosure [see NEC 680.26(B)(6)].

THE GRID

The bonding grid encompasses multiple areas within the swimming pool and pool areas which surround the pool.

Within the swimming pool; included components include the water, pool light and light assembly, hand rails, metal fittings 4” or larger, the concrete pool shell and reinforcing steel within the shell (rebar).

The outer surfaces around the water includes perimeter surfaces no less than 3 feet out from the pool and a height of no less than 5 feet from the ground. This includes paved, unpaved surfaces and any rebar or pipes within these surfaces. i.e. sidewalks, decks, etc… This also includes any object which has the potential of being a conductive surface. For example, the metal footing straps within footings where patio covers will sometimes connect, speaker brackets, light brackets, diving boards, slides, fencing, gutters, railing etc… The perimeter grid must be no less than 18-24” from the inside walls of the pool and 4-6” in depth.

The electrical equipment which includes the pump motors, pool covers, heaters, blowers, salt generators just to name a few.

Fiberglass swimming pools must possess an intentional bonding plate which is no less than 9 sq inches within the pools water.

The purpose for making these connections electrically to all metals parts is to ensure that they are all within the same electrical potential thereby reducing injury as created by stray voltages which are possible in the ground as well as the piping, (metallic or plastic both are susceptible to stray current) connected to the swimming pool system.

STRAY and contact VOLTAGE

All the metallic structural components and other metal fittings, wiring methods and equipment must be connected together to form an equipotential bonding grid. The equipotential bonding grid is divided into two (2) distinctive parts, the conductive pool shell (belly steel) and the perimeter surfaces (deck steel) (see photo 2). For the conductive pool shell, poured concrete, pneumatically applied or sprayed concrete, and concrete block (including painted or plastered coatings) are all considered conductive materials due to water permeability and porosity. Vinyl liners and fiberglass composite shells are not included in these bonding requirements and are considered nonconductive materials. For the perimeter surfaces, the equipotential bonding grid is to extend under paved walking surfaces for 1 m (3 ft) horizontally beyond the inside walls of the pool unless separated from the pool by a permanent wall or building 1.5 m (5 ft) or more in height. The deck or perimeter surface also includes unpaved surfaces as well as poured concrete and other types of paving and is required to be attached to the pool reinforcing steel or copper conductor grid of the conductive pool shell at a minimum of four (4) points uniformly spaced around the perimeter of the pool. For nonconductive pool shells, bonding at four points is not a requirement. The components and make-up of the conductive pool shell and the perimeter surfaces will be discussed in greater detail later in this article.

The bonding connection between the various components of the equipotential bonding grid can be made with a series of solid copper conductor(s) or with rigid metal conduit of brass or other identified corrosion-resistant metal. If a conductor is used, it may be insulated, covered, or bare, but cannot be smaller than 8 AWG. This bonding conductor is not required to be extended or attached to remote panelboards, service equipment, or any grounding electrodes. This bonding conductor is, again, simply for bonding of metal components together, it is not intended for establishing a connection to earth or a ground-fault return path.

The connection(s) must be made in accordance with NEC 250.8 by such things as listed pressure connectors or clamps that are labeled as suitable for the purpose and are to be made of stainless steel, brass, copper or copper alloy. Where pressure-type connectors are used, be certain they are sized to accommodate the 8 AWG copper bonding conductor and the steel reinforcing bar or whatever is being bonded. Consult the connector manufacturer’s specifications for the proper model connector. Some clamps or connectors are suitable for use with pipe only or with reinforcing rods only. Some of the clamps or connectors are identified for use with a certain size or diameter pipe only, such as ½ in. – 1 in. diameter trade sizes only. This requirement will also ensure a secure connection on what are often widely different sizes of reinforcing bar or rod and the 8 AWG bonding conductor.

If the connection will be covered with concrete or earth, use a wire pressure connector that is identified as being suitable for direct earth burial or concrete encasement, whichever applies.

The process of exothermic welding is an excellent way to bond the required bonding conductor(s) to reinforcing rods or bars. If the exothermic welding process is used, it is critical to use the proper form or mold. A proper form will be sized for both the reinforcing rod and the bonding conductor to be used. Also, be certain all the manufacturer’s instructions are followed. Too “hot” of a load may ruin the connection. Safe work practices and proper personnel protective equipment are required to avoid being seriously burned.

Equipotential Bonding Grid — Conductive Pool Shell

The equipotential bonding grid is comprised of two (2) different and distinct parts. The first of these two that we will discuss is the conductive pool shell. This conductive pool shell is sometimes referred to as the belly steel. The conductive pool shell is to be comprised of the following elements:

Unencapsulated structural reinforcing steel of a conductive pool, where the reinforcing steel is bonded together by the usual steel tie wires or the equivalent. If the structural reinforcing steel is encapsulated in a nonconductive compound or if unencapsulated structural reinforcing steel is not available or utilized at a conductive pool shell, a “copper conductor grid system” is the only Code-compliant alternative and is required to be installed [see NEC 680.26(B)(1)(a) and (b)].

If installed, this copper conductor grid system is to be comprised of (1) through (4) below:

-

Constructed of a minimum 8 AWG bare solid copper conductor(s) bonded to each other at all points of crossing (see NEC 250.8 for bonding connection provisions).

-

Copper conductor grid system must conform to the contour of the inground pool shell.

-

Must be arranged in a 300 mm (12 in.) by 300 mm (12 in.) network of conductors, uniformly spaced in a perpendicular grid pattern with a tolerance of 100 mm (4 in.).

-

Must be secured within or under the pool structure no more than 150 mm (6 in.) from the outer contour of the pool shell.

-

Equipotential bonding grid includes both the conductive pool shell (belly steel) and the perimeter surface (deck steel).

-

Perimeter surface consisting of conductive structural metal reinforcement steel (rebar). Notice the structural steel from the conductive pool shell (belly steel) bent over and tied to the perimeter surface (deck steel).

Bonding conductor (8 AWG solid CU) to pool pump motor.

Equipotential Bonding Grid — Perimeter Surfaces

The second element of the equipotential bonding grid is the perimeter surfaces or deck steel as it is sometimes referred to [see NEC 680.26(B)(2)(a) and (b)]. The perimeter surfaces are comprised of the following elements.

Unencapsulated structural reinforcing steel, which for the perimeter surface can consist of such things as structural metal rebar or welded wire mesh. Where structural reinforcing steel is encapsulated in a nonconductive compound or where unencapsulated structural reinforcing steel is not available or utilized, an “alternative means” consisting of copper conductor(s) would then be required to meet the following requirements:

-

At least one bare solid copper conductor installed sized at a minimum 8 AWG.

-

The conductor(s) are required to follow the contour of the perimeter surface (deck steel).These alternative conductor(s) must also meet the following:

-

Permitted to be spliced but only utilizing listed splices or splice kits.

-

Installed 450 (18 in.) to 600 mm (24 in.) from the inside walls of the pool.

-

Secured within or under the perimeter surface 100 mm (4 in.) to 150 mm (6 in.) below the subgrade.

For the equipotential bonding grid, a clear distinction must be drawn, and attention needs to be directed to the difference between the copper conductor grid system as an alternative for the conductive pool shell and the copper conductor(s) alternate means for the perimeter surfaces. This difference is the reason the Code separates these two distinctive and separate components of the equipotential bonding grid system. Each has separate requirements to achieve the same goal (bonding for the same voltage potential).

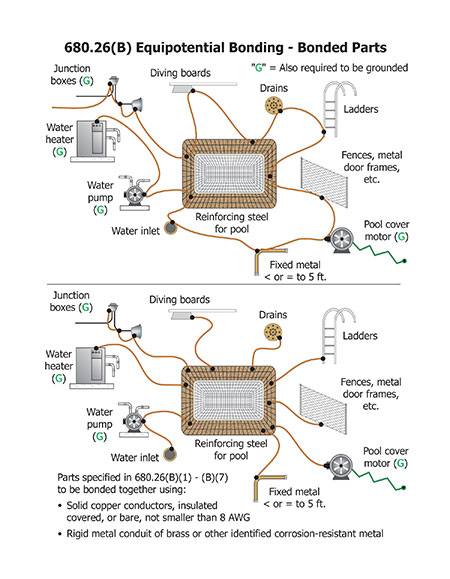

There is no Code requirement calling for this bonding conductor(s) to be installed “in one continuous length without a splice or joint.” This would be true if this conductor were a grounding electrode conductor [see 250.64(C)], but this conductor is not a grounding electrode conductor (used for grounding), it is a bonding jumper (used for equipotential bonding). Over the years, I have witnessed numerous installers and inspectors alike requiring this bonding jumper to be installed “in one continuous length without a splice or joint,” which is laborious and unnecessary. The same equipotential bonding can be achieved with a series of multiple short bonding jumpers from such things as ladders, diving boards, metal fences, etc., to the structural metal rebar that often makes up the conductive pool shell (belly steel) and the perimeter surface (deck steel) (see figure 2).

Figure 2. Equipotential bonding grid forms an equipotential bonding plane in and around the pool area. This bonding plane can be achieved with one “alternative means” bonding jumper (top) or multiple bonding jumpers (bottom).

ACCORDING TO THE IEEE INSTITUTE OF ELECTRICAL AND ELECTRONICS ENGINEERS , THEY PROVIDE A DEFINITION OF BOTH CONTACT AND STRAY VOLTAGE.

Stray Voltage: A voltage resulting from the normal delivery and/or use of electricity (usually smaller than 10 volts) that may be present between two conductive surfaces that can be simultaneously contacted by members of the general public and/or their animals. Stray voltage is caused by primary and/or secondary return current, and power system induced currents, as these currents flow through the impedance of the intended return pathway, its parallel conductive pathways, and conductive loops in close proximity to the power system. Stray voltage is not related to power system faults, and is generally not considered hazardous. (See also Contact Voltage) Note: “Conductive surfaces” as used in this definition are intended to include the earth and/or extensions of the earth such as concrete sidewalks and metal floor drains.

Contact Voltage: A voltage resulting from abnormal power system conditions that may be present between two conductive surfaces that can be simultaneously contacted by members of the general public and/or their animals. Contact voltage is caused by power system fault current as it flows through the impedance of available fault current pathways. Contact voltage is not related to normal system operation and can exist at levels that may be hazardous. Note: “Conductive surfaces” as used in this definition are intended to include the earth and/or extensions of the earth such as concrete sidewalks and metal floor drains.

THE FIX

Repairs to the bonding grid can be extremely complex. In cases where a bonding conductor is not installed anywhere, and in order to meet the requirements of the NEC section 680.26, the pool may require a complete remodel of the pool and surrounding areas of the pool.

According to many pool builders and pool professionals the removal of the decking if present is likely necessary to gain access to the pool body (shell) and rebar within in order to make a connection. It also requires gaining access to the light and light fixture niche to make connections there as well.

Note that “installing a ground rod does absolutely nothing to bond, repair or improve the bonding of the pool and subsequent protection of the public”.

EXAMPLES OF INJURIES CAUSED AS A DIRECT RESULT OF ELECTRICAL ISSUES WITHIN SWIMMING POOLS

EXAMPLE 1

November 8, 2013 – Charges have been filed against two suspects wanted in the death of a man following an incident at 9999 Westheimer about 7:40 p.m. on August 31.

The suspects, Jason Joseph Gorczyca (w/m, DOB: 3-26-78) and James Ray Pyle (w/m, DOB: 9-6-79), are charged with criminal negligent homicide in the 208th State District Court. The victim, Raul Hernandez, 27, of Richmond, Texas, was pronounced dead on Sept. 6.

Photos of the two suspects are not available at this time and neither male is in custody.

HPD Homicide Division Sergeant M. Holbrook and Officer I. Duplechain reported:

Mr. Hernandez was swimming with his family at the Hilton hotel pool at the above addresss. At dusk, the pool lights came on and people in the pool began to complain of being shocked. Hernandez swam to the deep end of the pool to help a child out of the pool. He was able to get the child out of the pool, but could not pull himself out. When bystanders pulled Hernandez out of the pool, he went into cardiac arrest and the bystanders performed CPR on him. Hernandez was then transported to Memorial Hermann Memorial City Hospital where he later died.

The Harris County Insitute of Forensic Sciences ruled Hernandez’s death an accident caused by electrocution.

A lengthy investigation was conducted by the Houston Police Department Homicide Division, the City of Houston Public Works and Engineering Department, and the Texas Department of Licensing and Regulation. The investigation determined the electric current was caused by a short in the pool light. The investigation also determined the wiring to the pool light lacked a ground fault circuit interrupter (GFCI) that would have immediately cut off the current in the event of a shock. The pool also lacked proper equipotential bonding. Both are violations of the National Electric Code.

The investigation revealed the Hilton hotel hired Brown Electric, Inc. in June 2013 to replace the wiring and bonding for the pool. Jason Gorczyca and his supervisor, James Pyle, performed the work in a substandard fashion. Additionally, Pyle did not obtain a permit for the work with the City of Houston.

EXAMPLE 2

CORAL GABLES (CBSMiami) – The family of a 7-year-old boy who was electrocuted in a swimming pool has filed a lawsuit against the company who made the pool light and a second company who serviced the family’s swimming pool.

Calder Sloan was electrocuted on April 13, 2014, while swimming in his family’s pool in North Miami. His father and attorney will hold a news conference Tuesday morning at 11:00 a.m. to discuss the lawsuit further with the media.

The wrongful death complaint claims he was electrocuted due to a faulty pool light and electrical grounding and bonding of the pool and lighting system.

EXAMPLE 3

Electrical safety is extremely important in and around public swimming pools. Australian Standards require that metal in and around swimming pools have equipotentially bonding.

Equipotential bonding is the practice of electrically interconnecting and grounding metallic objects in and around the pool. This is to ensure that if an electrical earth fault occurs, the current can be safely diverted away from bathers.

Some public swimming pools, especially older pools, have been constructed with either faulty or no equipotential bonding system, leaving bathers at risk and councils liable. Inadequate equipotential bonding in Australian swimming pools has in the past lead to electric shock and even death in some cases.

EXAMPLE 4

The CPSC and the American Red Cross are also warning swimmers that electrical hazards around a pool, hot tub or spa can lead to multiple deaths or injuries. This occurs when an individual becomes incapacitated by stray current in the water and one or more persons jump in or reach out to save the victim, resulting in multiple electrocutions or serious shocks.

In May 2002, a 14-year-old girl from Arlington, Texas, was electrocuted when wiring problems in an apartment swimming pool’s underwater lights charged the water with electricity. A 16-year-old boy was seriously shocked when he jumped in the pool to try to save the young girl. Another teenager used a fiberglass shepherd’s hook (a non-conductive device) to pull both victims from the water.

EDUCATIONAL VIDEOS BY MIKE HOLT